Links to previous parts of the series as well as links to articles about KPIs can be found at the end of the article.

The current series of articles focuses on the important KPIs every business must monitor. I have already written articles regarding this very important issue.

Part I of the series discussed KPIs every CEO must examine once a week or once a month and two additional KPIs that CEOs must address every time a deviation is reported. Quality Assurance KPI and the law of Work & Rest hours KPI.

Part II of the series presents the KPIs under the responsibility of Human Resources and financial managers.

Part III presented KPIs of the supply chain.

This article presents the KPIs under the responsibility of Production managers, Quality managers, Sales managers, Marketing managers and Engineering & Research, development managers. The KPIs are shortly presented with links to learn more about them in greater detail.

Operational managers

To achieve the best results, operational managers must focus on operational issues. They must not deal with purchasing, supply management or any other issues.

The first KPI: OEE KPI

(Overall Equipment Effectiveness) measures how many good quality products had been produced during a set period verses a theoretical production volume set in accordance with definitions of bottle necks.

OEE results are affected by machine breakdowns, maintenance, shutdowns, poor quality of products etc. It should be noted that it is not possible to reach 100% efficiency.

OEE is the best KPI to monitor production efficiency. It includes levels of keeping to the production plan, employees’ proficiency and engagement, product quality, machine maintenance etc.

To understand the importance of OEE I recommend reading my previous articles on the subject, here and here.

Frequency of monitoring must be at least once a day, but preferably throughout the day. Monitoring is performed by field managers. Electronic systems, (general name: MES - Manufacturing Execution System), which collect and send online data regarding products and workers, can be easily found these days. Data can be managed manually too, but the electronic systems are preferable for accuracy, speed, and online availability.

The second KPI is: Meeting the weekly production plan

Frequency of monitoring: once a week

The department of Production Planning and Control (part of the supply chain) is responsible for generating the weekly plan. The operational system is required to follow the plan. Of course, all must be done in cooperation and agreement between the departments at weekly meeting, usually on Tuesday or Wednesday, in which they discuss the weekly plan and its execution. The meetings must focus of the execution of the plan, not negotiations on the plan itself.

Weekly production plan is rarely practiced in industry although adhering to it create an excellent way to increase efficiency and save materials and labor cost.

Measuring system: A weekly production plan for the following week must always be completed by the end of each week. To make sure production was executed according to plan and there are no discrepancies between the plan and the actual number of items produced, it must be monitored at the beginning of the third week. Products that were manufactured outside the plan are regarded as products which were planned to be manufactured but were not. Weekly analysis must be done to understand the reasons for the deviation from the plan and corrective actions must be applied.

Working without a plan cause great damage to the business and yet, many managers often succumb to customers and sales representatives’ demands to expedite delivery or make other changes to the plan.

Each change to the production plan causes:

- Replanning the workforce: adding or reducing the number of employees on shift (which may entail overtime or cause hidden unemployment)

- Extra purchasing cost of raw materials unavailable in stock

- Extra transportation cost of raw materials to the manufacturing site.

- Extra cost of delivering the goods to the end customer’s destination.

To save costs, some companies may keep extra inventory, but that bears high costs too.

Required OEE score must be no less than 85%

The third KPI is Quality at first time

(Also known as FTQ- First Time Quality or FTR- First Time Right) It monitors good quality batches which were manufactured at first attempt. (No adjustments or salvaging). Every adjustment made to a manufactured tool cost money and substantially reduce company’s profit. In fact, profits are usually not high enough to allow costs of redoing. In the past, it was normal to measure the total number of good quality products. Redoing and salvation processes of scraped products were not monitored, and the cost not considered. However, it has always been one of the major “hidden” losses of manufacturing businesses. Muda causes great harm to businesses.

Measuring Quality products at first time advance improvements which increase company’s profit.

Fourth KPI - Materials’ waste

The aim is to reach zero waste of raw materials. Although it is somewhat a theoretical aim, it provides purpose and focus. During my coaching career, I have seen companies which achieved waste scores of nearly zero.

Cost of raw materials is the biggest cost in most manufacturing firms. It can reach between 40% and 70% of the sales earnings. Every percent saved on raw material means more profit for the company.

Measuring system: Look at the production plant as a box. How much raw material went in and how many products were manufactured.

Detailed measuring is required. An overall view doesn’t allow analysis and improvement. Detailed measuring is done at a batch level. i.e., quantity of raw material verses number of manufactured products.

Manufacturing plants, in which raw material is continuously used, find it difficult to separate exact quantities of raw material used for each batch. However, to analyze the root causes of waste and create corrective actions, it is necessary to understand the process of the batch manufacturing, considering the possibility of inaccurate of measuring.

Sales, marketing, or sales & marketing managers?

In many companies, sales managers are also marketing managers. In some companies, mangers might be titled marketing managers even though they are responsible for sales as well.

What is the difference between sales and marketing managers?

In short, marketing managers are responsible for creating demand and sales managers are responsible for supplying the demand.

Aspects of these two positions may overlap, but they are two different disciplines and often a person suitable for a marketing position is not suitable for a sales position.

Small companies may not be able to employ both sales and marketing manager. However, in small companies the budget for marketing is usually small or nonexistent anyway. These companies can use digital marketing which is a useful and effective way of marketing. For these companies it is worth considering outsourcing the digital marketing process.

This article relates to companies which employ both marketing and sales managers.

Sales managers

Sales create an opportunity to earn money. However, the transaction ends only

when payment had been received

First KPI of the sales manager is: sales vs targets

Performance of sales managers is measured by the volume of their daily, weekly, and monthly sales vs the target. The sales team is measured in the same way, individually.

The process of sale is made up of small actions. Each successful sale increases the company’s profit. For that reason, sales vs target must be monitored daily.

I know CEOs who receive online sales reports and check the sales rate throughout the day. Whenever they identify a slowdown, they call the local manager to understand what is happening. Pushing sales is a frustrating task. That is the reason salesmen are the only employees to be granted bonuses. Their need to periodically ease the pressure is understandable, and it is therefore crucial to monitor sales results every day.

Daily sales reports must reach all sales representatives, not only the CEO. The reports must include the actual sales data verses the monthly target and verses the relative target. (Relative target may be sales achieved during 40% of the month verses 40% of the monthly target).

A sale is completed only after payment has been received. To create an incentive for salesmen to complete the sales, bonuses should only be granted after the sale had been completed and not for invoices or debts that will be paid in the future.

Sales representatives have a continuous, direct contact with the customers. The sales reps, no other department in the company, must be responsible for collecting payment. The representatives must understand that their job is to bring in the money and it’s therefore their responsibility to receive payments.

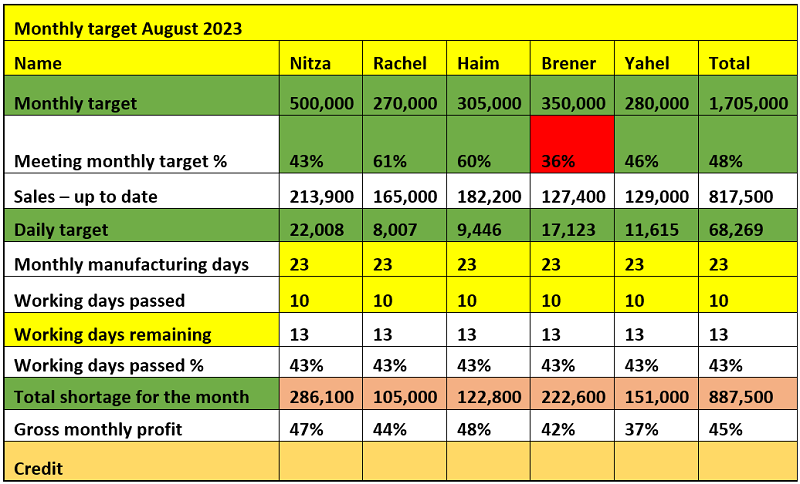

An example for daily sales control:

Karin, a young sales manager with a healthy intuition, operates the above sales sheet every day. I received her permission to publish the table with changes to the names and numbers. The daily report sheet is accompanied by a monthly report, monitoring the end of each month, throughout the year. This provides an instant, ongoing overall picture of sales versus the annual plan.

The benefit of the report is obvious, but it can create massive pressure on sales reps. To relieve the pressure, Karin often organizes social, bonding activities for the sales staff.

The second KPI: Gross profit of sales

The purpose of sales is generating profit, not only cash flow. To prevent salesmen, who automatically receive bonuses for every sale, and therefore might be prepared to sell at a loss or low profit, some businesses may limit the rate of reduction sales reps who are allowed to offer and sometimes even the reductions that area managers are allowed to grant. When sales managers’ performance is monitored according to gross profit verses target, they will encourage their team members to reach gross profit. Follow up on reductions is then less relevant.

The third KPI: New customers

New customers are the future of the business. However, salesmen often find it easier and more rewarding selling to old, loyal customers. This reduces their motivation to recruit new customers and therefore must be monitored as part of the manager’s KPIs.

Summary and recommendations

Every company has its own way and emphases but the KPIs presented above apply to all. CEOs are usually directly responsible for three to four KPIs and the rests are cascaded to the managers and staff under their responsibilities.

KPIs of the operational manager are:

- OEE (Overall Equipment Effectiveness)

- Meeting the weekly production plan

- First time quality

- Material waste

KPIs of the sales manager:

- Financial value of sales

- Gross profit

- New customers

These KPI reports should be monitored once a week or once a month accordingly.

Remember! Cutting corners may improve appearance but not company performance.

Links to previous parts of the series

- Important KPIs to run a business – part I: The KPI reports CEOs Regularly measure

- Important KPIs to run a business – Part II: Human Resources and Finance

- Important KPIs to run a business – part III: Supply Chain

Links to articles about KPIs

- Increase in Output and Efficiency using OEE measures

- The OEE Measure: Improve Efficiency and Maintain Delivery Times

- 4 Important Performance Indicators to Know

- Statistical Quality Control – What Is It? How To Use It? – The Last Chapter From My First Book

- Excellence, Quality, and Increased Profits through Employees' Involvement and Responsibility

- Just in Time Inventory Management – is there such a thing?

- How to Manage Dead Inventory and What You Can Get Out of a Yearly Inventory-Check

- Hotbeds of waste: Where we lose major money without noticing

- Does Improving the Organizational Culture Improve Profit?

- Clever marketing VS wise consumers: How does packaging affect consumers?

- How Can You Prevent Loss of Payments You are Owed?

- Sales and Marketing During and After the Coronavirus Crisis

- Blue Ocean Sales Strategy

- Defect analysis and solutions during production process, using fishbone method

- Fair Marketing's JUST Eye Fashion

- Our Work Method - Targets and Indicators as a tool to help Improve Profits and Performance

- How Much Are You Willing to Pay for Good Service, or How to Improve Your Customer Service

- Improving Company Performance, Profit and Strength by Working with New Targets

- Creating a Yearly Work-Plan – A Step-by-Step Guide

- Payment Collection - a Critical Process for the Existence of The Company

- Failure Analysis: To Arrive at the Root Cause and Create a Solution with the Five Why Method

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management