One of my sons once said to me that he had decided to continue to play basketball in order to be tall. Aren't all basketball players tall?

I was reminded of this remark not long ago, in a discussion held on Toyota's developed work methods. One of the senior management executives, a top expert in his field, said that Toyota could implement the methods discussed, particularly "Just in Time", because they were a large company.

I asked him what came first. Perhaps they were a large company because they had learned to develop and adapt innovative methods in their production processes?

The discussion took place following a defect detected in one of their products in a routine quality control inspection and, following investigation, it turned out that the warehouses were storing tens of thousands of defective items.

The CEO of that company led the business and marketing development and wanted to ensure that they would never lack product to supply orders, and therefore their warehouses were full of product that turned out to be defective.

The CEO of that company, like so many other CEO's, acts with premeditation, and when he needs to choose between being late with supply or unable to supply an order, and having large inventories, he makes the right choice (and in his case, the choice was very correct) and chooses large inventories.

Sales are the company's motor. They supply the orders, pay the salaries and serve as oxygen to the company.

However, the question really is whether the choice is only between two alternatives:

- Full inventories

- Or missing orders that will push their customers away and towards competitors

Aren't there any other alternatives?

Just In Time

There is actually one other alternative, and it's called Just In Time, according to which materials and parts arrive at the production line in the required quantities for production and are in the right place at the right time. No superfluous stocks or overfull warehouses.

Before we discuss this alternative, I would like to tell you of one more case.

Years ago, when I worked for a major company, one of our carton suppliers suggested they become our exclusive supplier, in return for which they would be connected to our carton inventory system. They would know at any given moment exactly how much we had in stock, would receive updates from the warehouse manager on the next week's production plan and would be responsible for ensuring that we work with minimal stocks and, at the same time, never run out of cartons. The stocks would sit at their site and we would only pay after we had received the goods.

The purchasing manager gave him a negative reply.

What are the advantages of working with the Just In Time method?

- As stocks are low, less storage space would be required.

- Less stocks, accurate work and sales orders would release working capital and ease cash flows.

- Less slow or dead stocks.

- When changing or improving the product as a result of customer complaints or necessary improvement processes, reaction time to the market will be swifter, with no need to destroy the earlier version of the product.

- When there are errors in production or planning (as described above), the cost of the damage is incomparably lower and the ability to resolve the situation is very swift.

And what are the disadvantages of working with the Just In Time method?

- There is only the narrowest room for defective production or errors, as stocks won't be sufficient with reworked stock or repeated corrections.

- We will need to have the strongest faith in suppliers and subcontractors being able to deliver the materials and parts on the required dates and at the required quality.

- The production system must be very reliable from the aspects of product quality and equipment (operation without stoppages).

- Urgent orders will only be supplied with great difficulty, or not at all (and urgent orders enable us to obtain a higher price or to gain an advantage in our customer-supplier relationships)

So how do we benefit from the advantages without paying for the disadvantages?

The first rule is to organize all the "why not" reasons. After we know what might happen in the worst scenario, we can plan accordingly and prevent failures.

Let's reexamine the method's disadvantages, or the "why nots" and then I will present preventative action.

- "There is only the narrowest room for defective production or errors". It's true that a production system must be reliable. That is why we will begin to measure the reworked product, or as they are better known, Right First Time, or First Time Quality product. This measure should lead to an analysis of problems, the initiation of preventative action and most certainly not a seeking of whom to blame. Improvement will be an unavoidable result. I recently published an article on this subject (available on my sebsite).

- "We will need to have the strongest faith in suppliers and subcontractors". No doubt this is a sensitive issue. Whereas the first "why not" is dependent upon us, with this one we are dependent upon others. But how can we ensure that our suppliers will work properly?

- First, we must decide that this is our new strategy and that we will adapt everything to suit it. We will initiate a dialogue with the subcontractors and suppliers of our raw materials. We can construct a system of prizes/fines with suppliers. However, in principle, we must be involved in the quality of their production. It isn't sufficient that they have an ISO system or other procedures. We must make sure they are implementing them. We can hire quality inspectors as subcontractors in Israel and around the world to perform inspections at various frequencies according to what suits us, and ensure that every piece of goods delivered to us bears the necessary quality, quantity and delivery date.

I am not sure I would trust Chinese suppliers on this issue.

And with regards to the cost of quality inspectors working for us as subcontractors, I feel sure (from personal experience) that if you compare their costs to the alternative costs of late deliveries and unstable quality, you will find it less expensive to maintain a quality inspector. You can find an article I have published on working with supplier here, on my website.

There are Israeli companies who supply companies like Boeing and whose parts arrive at Boeing exactly on time, at the required quantity and quality because this is a condition of to be or not to be.

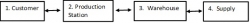

During my past company management, we wanted to supply parts to a company constructing buses in Spain. The bus production line moved slowly from one assembly station to another. Each assembly station used different parts, and everything arrived on time and at the required quantity and quality.

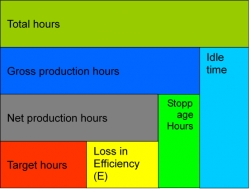

- "The production system must be very reliable from the aspects of product quality and equipment." Here, too, the right path is to measure, analyze and improve. The production line must be reliable, one way or the other. If we give up on the struggle for the reliability of our product, we will pay with large stocks (and the other troubles mentioned above), as well as errors, discarded and reworked product, and urgent, costly repairs.

The path is to measure, analyze and improve. There are a few potential improvement measures in this regard. I have published an article and slideshow on this, and I will soon publish articles on improvement in maintenance and construction of a preventative maintenance plan.

- "Urgent orders will only be supplied with great difficulty, or not at all." Not accurate. The slimmer our system, the cleaner it is of slow and dead stocks, the more reliable our systems (following the improvement process I detailed above), the more flexible we will become, thus improving our reaction time for customers.

At the same time, just as we must initiate a dialogue with suppliers and agree on a work method, it would also be essential to initiate a dialogue with our customers.

The changes that are imposed by us on the market are not divine ones. I know of several small and large companies who work in the retail market or with other businesses (B2B) and who have succeeded in planning their production at a very high level of reliability and with a minimum of changes. I am also aware of other companies who are sinking under the burden of changes and impositions demanded by strategic customers. The difference begins in your company's approach.

I have published articles on production plans (available on my website), and in the near future I will be publishing an article on dialogues with the market.

An intelligent construction of inventory

I once read that the Japanese have also developed the Just In Time method for maintaining inventory, and rely on it in their production. Japan lacks natural metals and minerals and therefore maintains inventories of metals at their ports.

The lower we descend on the product tree towards the roots so that our inventory can serve more products or we are assisted by different packaging according to various destination markets, the greater our advantage in maintaining a specific quantity of inventory.

Working intelligently will maintain a balance between the principles I detailed above and the inventory that can serve the greatest number of end products.

Summary and Onwards on Our New Path

As I wrote in last week's article, "Habits and Patterns of Thinking", we must first define our new objective. Instead of carrying only our flagship sales at the top, we must raise the new flag of a smarter and more sophisticated production system that will serve sales as well as contributing to company profitability.

If we continue in our old way of thinking and act as we always have, we won't be able to change our results. Instead of confining our objectives to production limitations, we should suit our production and the entire chain of supply to company objectives that serve the optimal goal of increasing company profit and strength.

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management