Links to previous articles in the series as well as links to articles regarding important KPIs to run a business can be found at the end of the article.

The current series of articles focuses on the important KPIs every business must monitor. I have written articles regarding this very important issue over the past few years. However, the current series presents KPIs in a concise form, easily expanded, when required.

This is part VI of the series. Important annual KPIs and a summary of the ways to achieve improvements by measuring, monitoring, analyzing, and implementing will conclude the series in part seven.

Gender distribution in business

I was recently asked about gender distribution in business and the proportion of female vs male managers. This was not the first time I was asked this question. In my previous articles I always referred to male and female managers equally as, in my opinion, both genders are equally suitable for any role or position in the company. I hope and believe that in all organizations, including my readers’, managers are chosen for their skills, knowledge and compatibility regardless of their gender.

The engineering manager

The role of the engineering manager is to secure the present and the future of the business.

To secure the present, engineering managers are responsible for the equipment availability, i.e., all machines and other equipment must be operational and available when required. Engineering mangers are also responsible for implementing future technologies that advance the business to lead the market competition. Lack of investments in new technologies will keep the business behind and force the company to lower prices to stay in the market. However, fast developing, innovating technologies will provide the company great advantages over its competitors and push the company to lead the market.

Measuring and improving the present situation

First KPI: MTBF = Mean Time Between Failures

MTBF is the most important KPI to measure total downtime of the production line. It measures the average time between breakdowns. A high number of unexpected downtimes over a set period decreases the time between the downtimes.

How to measure? (Detailed explanation in the link)

Assuming the business operates 24 hours Sunday to Thursday and 6 hours on Friday, total weekly hours 24 X 5 + 6 = 126 hours a week.

Assuming there were no downtimes during the week, we add 1 (as we cannot divide the sum by 0), and thus the weekly result would be:

![]()

In the same way, if there were 4 downtimes the result would be:

![]()

The second KPI : availability of equipment or the length of time machines are down due to breakdowns

After measuring the number of breakdowns, we measure the length of time each downtime lasted as a percentage of the total operational time.

The cost of a short downtime equals the cost of a long downtime. Why?

Machine downtime cause:

- Additional machine setups. Machine restarts carry an extra cost of labor and materials especially in continuous processing lines.

- Additional scrap. Incomplete products that manufacturing has not completed during production, cannot be sold.

- Loss of production capacity during downtime.

- Loss of employees’ labor time.

- Long downtimes cause high losses for the company, but short, frequent downtimes cause the business high losses too.

So, after counting the number of breakdowns (short and long) we measure the time each one lasted.

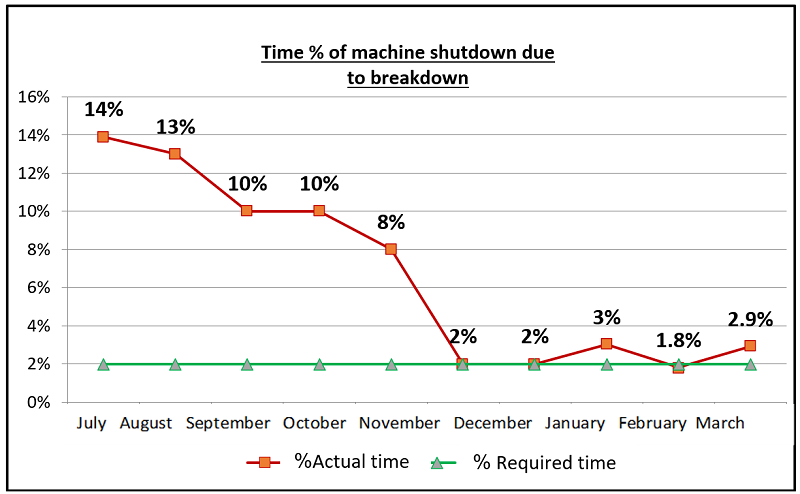

The table below demonstrates the swift recovery of a firm I worked with, after implementing these KPIs and the corrective actions which followed.

Improvement starts with measuring. Root cause analysis must precede implementation of corrective and preventive actions.

Creating preventive actions

Analyze the causes of one breakdown per week. Follow it by implementing corrective and preventive actions. A team of three employees, consisting of maintenance staff and operators, will use the fishbone method to discover the possible causes of the breakdown.

The team will then select one or more causes and use the 5 Whys method to find out the root causes.

This will identify the ways to shorten and even prevent future machine breakdown.

Visual control

One of the reasons downtimes take a long time is not knowing they happened, which is a form of bad communication.

Toyota developed the Visual control system which identifies machines’ stops.

Planed maintenance

Preventive maintenance is an extremely important tool, one might even say a crucial one, but it is only a tool. It is not an aim and therefore is not measured.

Good planning of maintenance will improve the two KPIs above.

Third KPI: Financial efficiency

Hold on! Why is financial efficiency the third and not the first KPI?

The first two KPIs aim to achieve production and financial efficiency of the entire business manufacturing process, whereas the financial efficiency KPI relates only to the financial conduct of the engineering system. The aim is to monitor the maintenance costs of the business.

Solving an unexpected problem is always more costly then preventing it via planned maintenance. However, planned maintenance must be optimal. In other words, money should be spent only for good reasons. Keeping unnecessary stock of spare parts should be avoided. One spare part must be stocked for each potential problem and a spare parts inventory must be managed accordingly. However, the number of items of each spare part in stock, will be determined by its cost, the difficulties in locating it and the time it would take to arrive on site.

Measuring financial cost will focus engineering managers on planning the quality and availability of spare parts, i.e. the balance between quality, cost, and shelf life of the parts in stock.

Building for the future

The second responsibility of the engineering manager is to build the company’s future abilities.

However, measuring future success is complex. Hindsight learning by analyzing whether the maintenance manager had taken the right decision is important, but it is not enough. Mistaken and successful decisions of the managers must be assessed in real time to make sure that actions are taken to achieve a company’s goals and objectives.

Who defines the directions of the company’s development?

The CEO defines the future strategy of the company and, based on information generating from the market, decides which direction the business should take. CEOs must focus on future trends and ways to attract customers. They should focus less on the directions their competitors take. Engineering managers are responsible for presenting the technical and mechanical solutions for the required future strategy.

Measuring

A good way to measure the performance of engineering managers is by monitoring the ongoing projects defined by the CEO for the engineering department. A good way to manage the projects and follow advancement is by using Tomorrow’s plan. Tomorrow’s plan is a tool developed by Dubi Shor based on the Theory of Constraints (TOC) of Dr. Eliyahu Goldratt.

Research and development manager

R&D managers deal with the future. They develop projects which advance the company’s future. A good R&D manager takes part in defining the company’s future, but the final decision is the responsibility of the CEO. Substantial projects are presented to the management board who often make the final decision: deny, or delay to a later date.

R&D projects expose the company to difficulties and unexpected obstacles. The R&D manager must be able to overcome these difficulties and meet the business objectives. I recommend reading how Toyota took the decision to develop the Prius car and the way it succeeded.

Performance of R&D managers is measured by four KPIs which monitor the advancement of the business operational abilities and the managers’ general contribution to advance the company.

First KPI: Meeting the plan

Here too, the best way to achieve the goals is by using Tomorrow’s plan, an excellent tool to plan, monitor and ensure that work is performed according to plan, including measuring the rate of advancement.

The second KPI: Time to market

The length of time it takes for a product to reach from the initial developing stages to the sale point. Measuring will be done by plan vs actual.

The third KPI: Time to profit

The length of time it takes for a product to become profitable. Measuring will be done by plan vs actual

The fourth KPI: Time to volume

The length of time it takes to reach a substantial sales volume. Measuring will be done by plan vs actual

Summary of R,D&E

An understanding of whether R&D managers are excellent at their jobs or should be replaced, can be retrospectively reached intuitively. However, business cannot be conducted on intuition alone. R&D managers’ performance must therefore be measured. Unlike most KPIs, which provide an online picture and therefore enable real time problem solving, measuring in retrospect can only provide an estimation of the R&D manager’s performance and therefore delays the decision whether to keep or replace the manager.

Summary and recommendations

KPIs of Engineering managers:

- Availability of equipment: measured by three KPIs

- MTBF (Mean Time Between Failures) or average time between downtimes

- Availability of equipment or length of time equipment is inoperative due to breakdowns

- Financial efficiency or cost of maintaining spare parts availability.

- Building the company’s future technology: best performed using Tomorrow’s plan a tool to follow projects’ performance.

KPIs of R&D manager:

- Online monitoring of meeting plans and overcoming unexpected obstacles and difficulties.

- Time to market

- Time to profit

- Time to volume

Despite the difficulties in measuring R,D & E performance, there is no better way to advance and improve but by measuring.

Links to previous articles in the series

- Important KPIs to run a business – part I: The KPI reports CEOs Regularly measure

- Important KPIs to run a business – Part II: Human Resources and Finance

- Important KPIs to run a business – part III: Supply Chain

- Important KPIs to run a business – part IV: Operation and sales

- Important KPIs to run a business – part V: Quality and Marketing

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management