Many companies I have encountered search for ways to save "in the spotlight", meaning areas where it is easy to see and to attribute to a particular focal point in pricing – for example, purchasing, defective product, work costs or logistics. And an action whose objective is to strengthen employee bonds falls under Welfare and is usually considered a luxury, ending up being the first thing to cut.

Waste that is "hidden from view"

At the same time, we ignore everything that's a little hidden from view, particularly expenses that don't fit into the designated pricing section. For example, where do we list the high cost of employee turnover (hiring, training, learning curve), the high rate of absenteeism, late or partial supply of orders, usually resulting in high and unnecessary set-up costs (zip-zapping among batches in an attempt to satisfy everybody), urgent and expensive freight, excess stock in the production process, particularly surplus stocks and defective product we try to salvage, etc.?

When we run after our own tails, looking for efficiency measures only in pricing sections in the accounting department – not examining the entire picture, and looking for unnecessary costs with a view only locked on accounting registries, we may exacerbate the loss and the lack of efficiency instead of improving them.

Two examples

Defective product. We all understand that if we have defective product, it's wasteful. But if we try to salvage the defective product, as will certainly occur more than once, the chance is greater that we will increase our loss. Very few products have large enough profit margins to support reprocessing or repackaging. Even intermediary storage due to slipups and late packaging will almost always be an expense the product cannot bear and will increase losses instead of making things more efficient.

In this case, we need to focus on investigating the core factors responsible for defective product, and to measure not the rate of defective product we managed to reprocess or have discarded, but rather the rate of product we did not manufacture correctly the first time (a measure called First-Time Quality or FTQ). Only this way can we prevent defective product. In the meantime, the unnecessary expense of reprocessing (salvage) will be divided up among various sections in the accounting department and becomes easy to overlook.

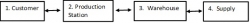

Non-maintenance of supply dates. When a company does not maintain its supply dates, their customers will begin to pressure the CEO or other managers to deliver their goods on time.

Each manager attempts to intervene and change the production plan, with the CEO above them. The damage incurred by changing the production plan can be enormous. First, there is loss of valuable production time due to stoppages and unnecessary setups, resulting in an increased delay of orders to follow. Second, there is usually waste of materials during the additional setups. Third, a change in production plan may require urgent, expensive supply of materials, down time on a production line or shortage of employees and an urgent call for overtime (staffing is implemented according to the production plan and is not conducive to change).

In this case as well, the customer who is angry with the CEO will be adequately supplied, but the cost and the delay in issuing full orders has increased. Except that again, the damage will be distributed among the different pricing sections and we won't see it.

Additional examples: Low Employee Motivation, working without Obligatory Weekly Planning, inaccurate management of inventory (Low Inventory Compliance), Multiple Products, and more.

Toyota's definition of hotbeds of waste

Decades ago, Toyota defined seven focal points of waste (Mudas) in their newly developed Toyota Production System, or as the West refers to these methods coming out of Toyota, "Thin Production".

The management and production methods that have blossomed out of Toyota's Production System are popular today at many international companies and have assisted in significant efficiency and increased profitability, and I recommend learning from them.

Toyota's definition of waste is any time we perform an action that:

- The customer isn't willing to pay for (by the way, we will probably have to take these kinds of actions sometimes, but we should minimize them as much as possible).

- Doesn't change the product or information.

- Requires salvaging – the product or service is not at the appropriate quality the first time (FTQ).

According to Toyota's definition, there are seven major areas where waste occurs:

• Defective product

• Overproduction

• Transport

• Waiting

• Surplus stock

• Unnecessary/Excess motion

• Inappropriate Processing

Let's look at this in detail:

Defective product. Every production of goods that do not comply with customer requirements and are discarded, with new production as a result, is, of course, a waste. Even the search for the reason for defective production is a waste. But it is a necessary waste in the goal for improvement. Instead of continuing to direct the same routine of production and salvaging, it is our responsibility to galvanize our employees and, with an improvement team, break it down into core factors of defective production to correct and prevent in future.

In this context, I will also state overweight packaging (for which the customer does not pay). This is a major waste. To decrease surplus weights, for example, we need to work with Statistical Quality Control and greatly decrease the weight discrepancies for each bag or packaging unit. In this way, we can fairly closely attain the average weight for the nominal weight listed on the package, without being in danger of being underweight.

I meet with a lot of companies who save on the "waste" of improvement teams and employee involvement, preferring to continue coping with defective production and reprocessing, resulting in costs many times higher.

Surplus stock. Any production of surplus quantity by mistake, or so as not to have to switch product during the night shift ("saving" on professional employees during night shifts), or to extend a production batch in an attempt to be efficient, incurs surplus storage. Surplus stocks take up a lot of room, which, of course, costs money; the goods may also spoil or lose their freshness, never mind food companies, pharmaceutical companies and others, who demand traceability, and lose it completely.

In this context, we can also include the introduction of production and storage of finished product that is not intended for the next shipment. As long as the employees and the machinery keep working, right?

Transport. Every movement of product above the required minimum is a waste. The fear, of course, is that we may consider everything that happens today and that we are accustomed to as being within the "required minimum".

Therefore, I recommend you begin with a measure of how many urgent shipments you have of product supplied late to angry customers, or urgent shipments to bring in raw materials for unplanned production. This measure is a necessary condition for improvement.

Continue to measure the number of times materials have left the warehouse for the production floor and have been returned to the warehouse at the end of the day. Or surplus stocks that get in the way and are moved from place to place. If you are a company providing a service, measure how many times a service person is sent again and again, when the problem was not resolved the first time they visited the customer.

Waiting. This can refer to employees waiting for production to begin (first product approval, faulty machinery, shortage of raw materials, etc.) or products awaiting processing.

Every waiting period of products in the process takes up space, increases the confusion on the production floor and, no less important, distances the receipt of income from the date of expenditure on materials, and from work expenses, also hindering cash flow (in this context, we can learn from the Cash-to-Cash Cycle measure.

Surplus stock. Any stock will incur costs. Some of it is necessary, and therefore we will determine the minimum optimal quantity of stock (I'll define this in a minute).

First, I will briefly summarize what was written above: the high costs of stock stem from their effect on cash flow, the space they take up (space costs money and we might frequently rent warehouses without thinking of the accumulating costs), the disorder – the greater the surplus stocks, the higher the chance that managing it won't be optimal and expenses will increase (for example, we might order materials that we already have or might not order materials needed for production), or have a detrimental effect on its quality and freshness.

What is the minimal optimal quantity? Of course, the quantity isn't absolute and we might always encounter extreme situations where the ship hasn't arrived, there's a port strike, or a war, etc. If we accept that any surplus stock creates unnecessary costs or waste, then we can work to prevent it in a number of ways.

First, I recommend using the KanBan method (also developed by Toyota), while striving to receive materials Just In Time. The open question is how much security stock we should keep.

In this regard, let's consider the following factors, while constantly remembering that the counter purpose is to minimize security stocks to zero (meaning, to keep stocks recommended by the KanBan method and no more).

So let's consider:

- Costs of stock (purchase price and the space they take up).

- Damage from lack of product quantities (for example, stoppage of entire production line and high fines paid to customer or loss in sales)

- Speed of making up the lack (is it available domestically or do we need a special delivery from overseas), do we have other production plants, which would enable us to keep acentralized security stock?

- How likely is it for something unpreventable happening to disrupt our supply of the relevant materials (strikes, wars, earthquakes, storms, etc.)?

Transport. Any unnecessary moving around by employees causes great waste that isn't attributed to any pricing section and isn't identifiable.

Imagine a maintenance person who comes to fix a machine without a fully equipped, organized tool box (this kind of toolbox is "very expensive"). How many times has he unnecessarily walked back and forth to the tool room, perhaps stopping on the way, chatting with friends, maybe even stopping for a smoke and almost sure that he needn't hurry (because "if management is saving money on a toolbox, I guess a rush repair isn't that crucial")? Now think about the cost of the time the machine isn't in operation, or the down time of the employees waiting for the machine to be repaired. Or the unnecessary movements of employees to bring materials that are lacking. So how do you improve this?

Measure and analyze using an improvement team of employees and strive to minimize moving around. For instance, when changing a production batch or a casting mold at a plastic factory, sketch on paper the "wanderings" of the employees involved. Now tell the improvement team to make things more efficient. You will receive amazing ideas.

Processing. The processing of a product involves a chain of costs that are intended for product manufacture at the quality defined by the customer.

From here, the potential creation of waste is high, or, to put it in a more positive way, there is a good opportunity here for efficiency. Are we manufacturing the product the best and most efficient way possible?

It's been seventy years since Toyota developed their production methods and it's still true for them that "there is always a better way".

Are you also making continuous efforts to improve your efficiency?

I suggest that you occasionally check to see if you have a relative advantage in producing your product, in whole or in part, on your premises. Perhaps you might be assisted by a subcontractor and purchase various components instead of manufacturing everything on your premises?

To continue to be efficient in the processing itself, I always recommend involving and engaging your employees.

There's a very good reason for employee involvement being one of the basics of thin production.

I frequently write about this in my blog, so I will state very briefly:

Employee involvement has three major advantages.

- First, the CEO and management contribute their knowledge all the time and like all of us, they may be expected to follow the same routine. New ideas will come from other people or new sources. Every employee has knowledge and information, and a different way of thinking. A variety of ideas might ensure a breakthrough.

- Second, when we involve our employees in problem-solving, we unite them with us in the company objective.

- Finally, the result of the two points above will be a dramatic improvement in employee motivation.

Summary and recommendations

This time, I've tried to cover a broad and in-depth subject. I began with a presentation of the attempt to search for the coin in the spotlight – to settle for the costs in waste that we see and that are usually only the tip of the iceberg.

The depth of this subject, the study of the Mudas or types of waste defined by Toyota have necessitated a longer article than usual, and yet, I have still tried to be as brief as possible.

The solution is through the links I've included (to many articles I have written over the five years of this blog's life, and a few Wikipedia links) for anyone interested in delving into the subject further.

As usual, the fear in this broad coverage is that it might stop you from digging deeper.

I recommend beginning step by step. What is always true is true here many times over. Take one factor each time, master it and only then go on to the next step.

And of course, whoever wishes to delve further and learn more is welcome to contact me personally.

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management