Links to articles regarding useful tools for successful management can be found at the end of this article.

An article, published in The Marker newspaper on February 8th, 2017, quoted the Israeli Ministry of Finance saying that “20% of Israeli citizens pay 85% of the national Income tax”. This statement demonstrates the Pareto principle, or ”The rule of 80-20”.

The Pareto principle is named after the Italian economist and sociologist Vilfredo Frederico Damaso Pareto (1848 – 1923) “The Pareto Principle – Rule 20-80”. who found that in most cases, 80% of the results are achieved due to the contribution of 20% of the active factors involved. He noticed that, in his time, 80% of Italian wealth was held by 20% of Italian citizens.

An article published in Globs magazine in July 2023, stated that the top two deciles in Israel were responsible for 92% of Israel national income tax, though their contribution towards the total government income from taxes was only 62%. This data is supported by ChatGPT4.

These numbers may be interesting or even sensational on a macro level, but how is it connected to the Pareto principle?

How can the Pareto principle help us?

The Pareto principle helps us priorities our resources.

Let us assume that we wish to improve the company’s profitability. To do that, we look at the performance of each product in the company’s catalogue.

Assuming the company sells 20 products, the items are listed from the products generating the highest profit at the top of the list to the products generating the lowest profit at the bottom of the list.

According to the Pareto principle, there is a good chance that the first four products on the list produce around 80% of the company’s revenues. If we focus on improving the profitability of these four products, we will achieve substantial improvement of the company’s profitability in an effective way.

The principal is not always exactly 80-20 but usually very close.

The aim of this article is to examine the cases in which the distribution is not exactly 80-20.

First, let us look at an example that clearly demonstrates rule 80-20. The example below appeared in one of my previous articles explaining the rule.

80-20 example

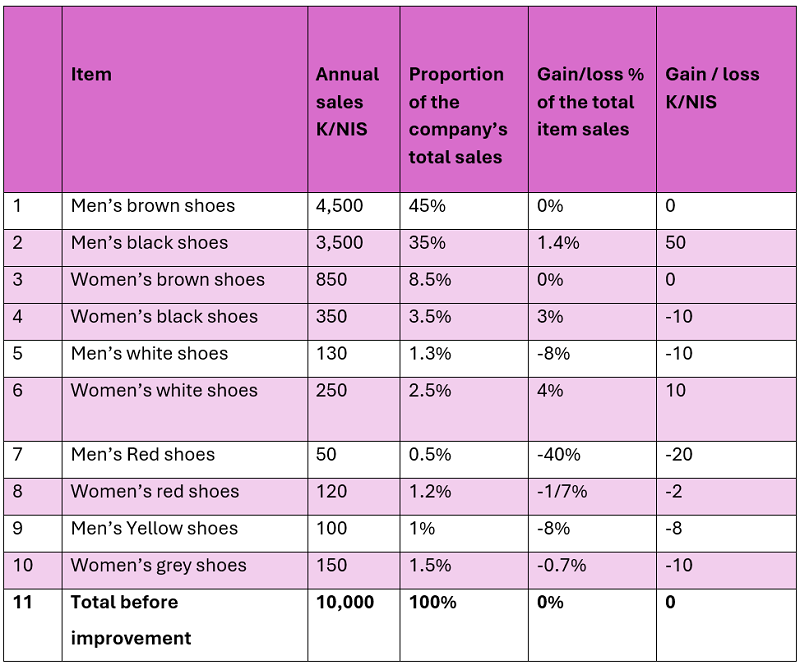

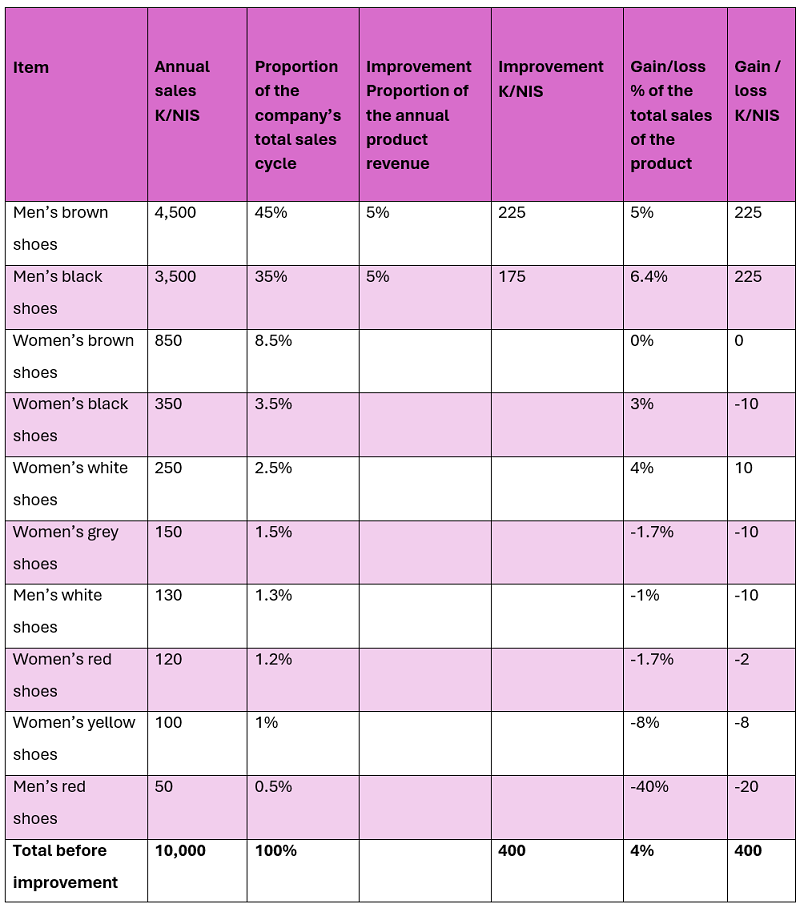

A company which manufactures men and women’s shoes sells 10 models. The company’s sales are 10 million NIS per year. The company breaks even: no loss and no gain.

The table below presents a list of the items, sales, gain, and loss of each item.

Rearranging the data from highest to lowest sales volume will reveal that 20% of the products (2 out of 10) are responsible for 80% of sales volume. Assuming we have the resources to deal with only 2 products, improving the profitability of these two products will achieve the best possible productivity results for the business.

The numbers in the above example had been altered to perfectly fit the pareto principle. The numbers in real life are usually close to 20-80.

What do we do when the Pareto principle is not applicable?

80-20 rule is common but not always applicable.

I once worked for a company that sold a few hundred types of products. Profit was down and urgent improvement was required.

Each product was examined for the level of its contribution to the company’s profit.

Profit contribution value was presented by a calculation of the average number of items sold of each produce, adjusted to its relative importance, and the gross profit it generated, i.e. the total number of sold items of one product times the gross profit from that item. The data was uploaded onto an excel sheet, sorted by to the product level of contribution, from highest to lowest.

Due to the high number of products (a few hundred), 20% of the total contribution to profit was generated by less than 80% of the total number of products. It was not feasible to improve the results by dealing with tens of products, i.e. the Pareto rule did not apply.

What should be done?

I recommend focusing on a list of between 100 and 150 products and rating them from highest to lowest sales value. A group of 100 to 150 products may present a situation in which 20% of the highest contributors present only 50% to 60% of the total profit value. The Pareto rule may not apply but the principle does. i.e. the principle of prioritizing resources.

Another example, from an expenses viewpoint

Small manufacturing plants, which are subsidiaries of larger businesses, may not be exposed to the level of contribution that the product they manufacture have on the total profit of the company. In these situations, efficiency will be achieved through cost of materials. i.e., a list of the raw materials will be made and sorted from highest to lowest cost of purchasing. In other words, calculating and rating the average volume and price with adjustments for the relative importance of each element.

When 20-80 principle is not applicable, resources must be invested in the top 20% highest volume of the materials used.

However, again, the 20% materials may not present 80% of the total cost. In that case we shall follow the example above: i.e. 60-20 rule or even 60-30 rule.

Summary and recommendations

Vilfredo Pareto found that in many cases, 80% of the results are generated by 20% of the factors involved in generating the results. This principle is called the Pareto principle or 80-20 rule.

The Pareto principle enables us to best prioritize the use of our resources by focusing on the factors that have the most impact on the results. Focusing on 20% of the causing factors will improve the business results. The same process must be implemented in cases where the 80-20 rule is not applicable. i.e. the same principle of prioritization applies in all cases.

Links to articles regarding useful tools for successful management

- What is the Pareto Principle and how can it assist us?

- Pareto principle or The rule of 80-20

- Defect analysis and solutions during production process, using fishbone method

- Brainstorming – The Basic Tool for Problem-Solving and the Development of Creative Thinking

- Teamwork – How important is it and how do you create it?

- How to create winning teams?

- Increase in Output and Efficiency using OEE measures

- The OEE Measure: Improve Efficiency and Maintain Delivery Times

- What is the Kanban system and how can it help us both in our businesses and at home?

- Working with Lean Canvas and Why It's the Best Tool for New Startups or Products

- Can We Apply Lean Production without Employees?

- Statistical Quality Control – What Is It? How To Use It? – The Last Chapter from My First Book

- The flowchart – a tool for efficiency and clearing bottlenecks in processes

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management