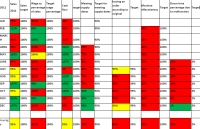

What are the most successful management methods used in Israeli Industry? Which are in common use, and which are able to bring about success?

Earlier this month I published the first part of the management survey results – with answers from approximately 350 managers. The first part examined the 13 methods comparatively, and presented the fascinating results regarding their levels of familiarity to managers, use, and success as reported by managers who had employed them.

In this part I mean to focus with more detail on each method, and see the differences between the levels of familiarity with the method and its use, and the success it generated.

As you'll see, there are methods which are widely used but fail to generate success, while contrastingly there are methods which are rarely used, but the majority of managers who've used them report success.

The first part of my analysis taught us about the differences between the various methods. This part will teach us about each method – which are in use, and which result in success and improvement?

In this article I'll present the detailed voting data for each of the 13 methods examined in the survey and discuss some insights I have about it.

As always, I'll be happy to hear your insights, which you can publish in the comments below.

Contents:

- Creating a company vision

- Creating a company strategy

- Using periodic work-plans

- Using key performance indicators (KPIs)

- Setting Quantitative goals

- Improvement teams

- Brainstorming

- Sorting and prioritizing ideas

- Flow-charts

- The pareto principle

- The fishbone method

- The 5 whys method

- Go See Think Do method

- Summary

[Normalizing the data: how was this data measured in the survey?

In order to achieve reliable results regarding the level of success working with each method – we removed from this part all the participants who reported having no experience with the method or not knowing it. Someone who has no experience with a method can't report success or lack of it, naturally. That is of course also the case with someone who doesn’t know the method.]

Creating a Company Vision

A vision is a phrase or a few sentences defining for the organization its raison d'etre, its main field of action, what drives and guides it, and where it's headed. The vision is a guiding principle – a compass which directs all employees, and from which goals are drawn.

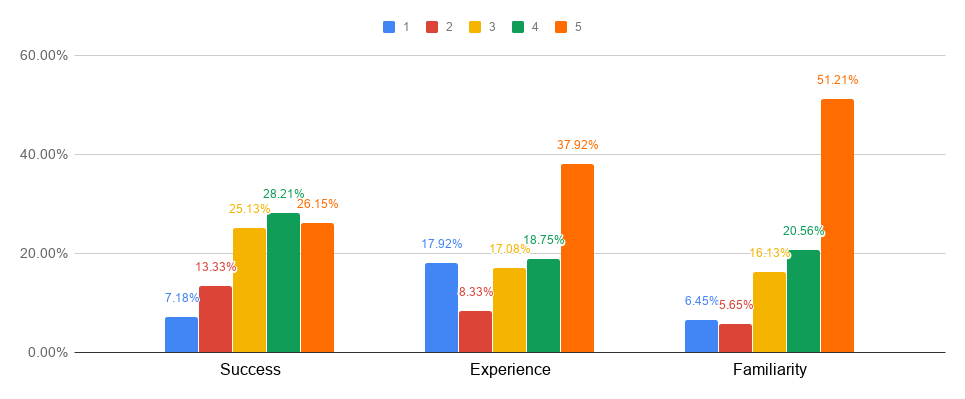

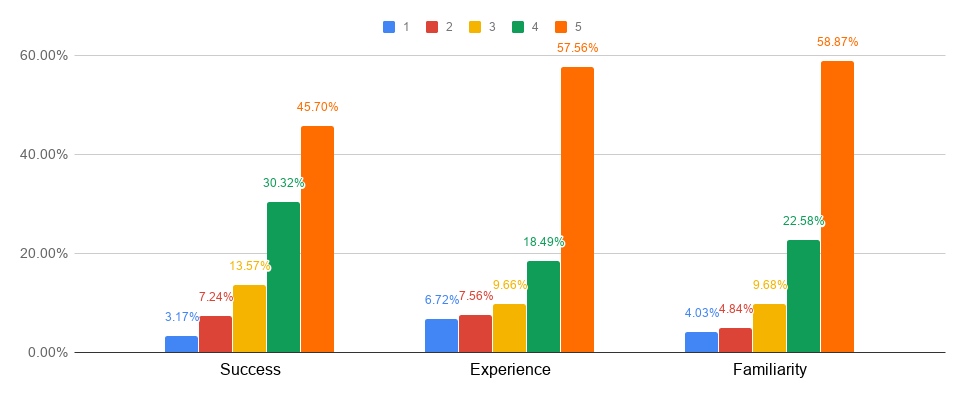

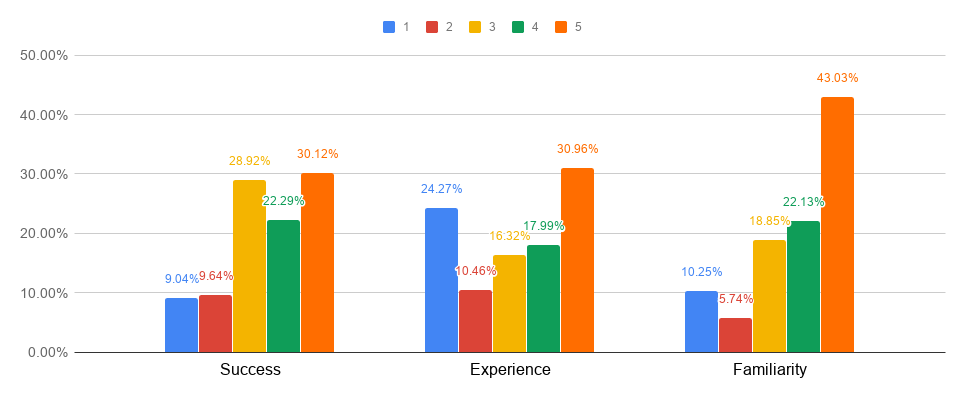

According to the data, we can see that 71% of participants are familiar with the method and chose 4 or 5 for this question, and only about 12% aren't familiar with it at all and chose 1 or 2.

56% of participants have experience with creating a company vision, compared with 26% who have no experience. But when we come to the question on success we can see that about 54% have had success with it.

It's interesting that this method has one of the largest difference between the percentage of participants who answered 5 in the question on familiarity, and those who answered 5 in the question on success. As I wrote in the previous part of my analysis, this might indicate an incorrect use of the method, and inability to connect the vision to the company's success, and at times maybe also a lack of actual connection between the two.

I'll mention that I've come across quite a few companies who publish a vision on their website which is purely a marketing tool, and isn’t used by them in their routine operations.

Perhaps more importantly, the company's employees (including managers) aren’t familiar with the vision at all. If they don’t know it – how can it guide their work? And if employees don’t implement the vision, it's no wonder it doesn't bring success.

Creating a Company Strategy

Creating a company strategy is an essential part of its success. It determines the direction the company is headed, is derived from the vision, and from it the work-plan is drawn – beginning with the products or services supplied by the company, the market in which it chooses to operate, the employees it will hire – if, of course, the company's work-plan is indeed drawn from its strategy, as it should be.

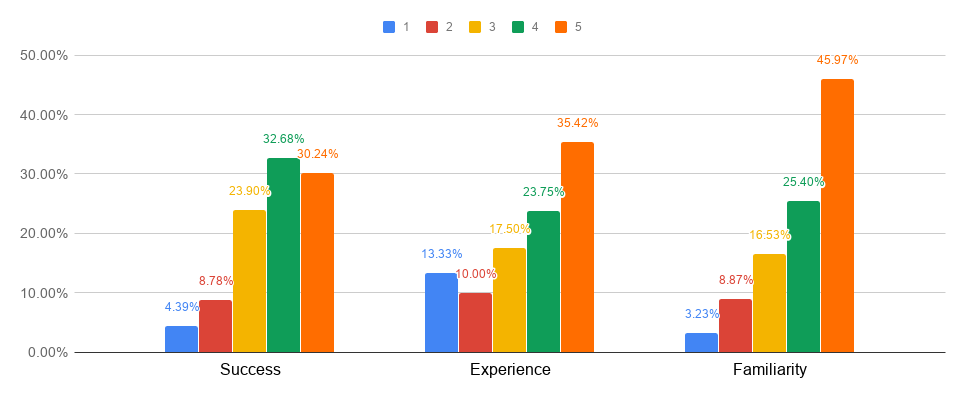

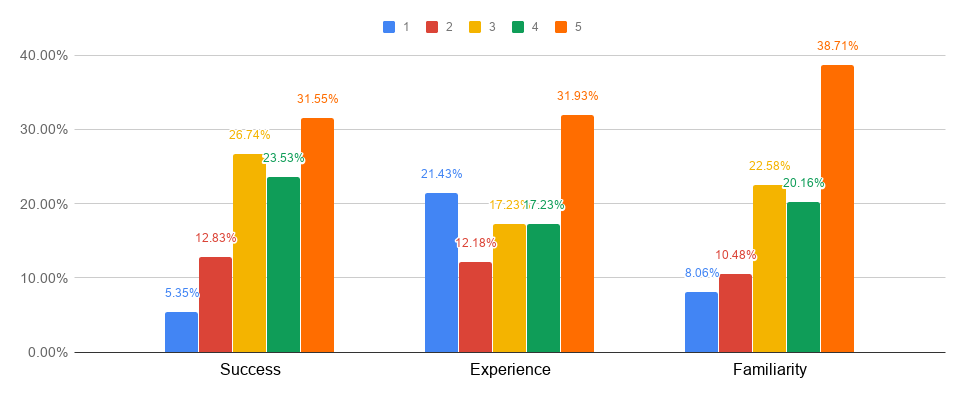

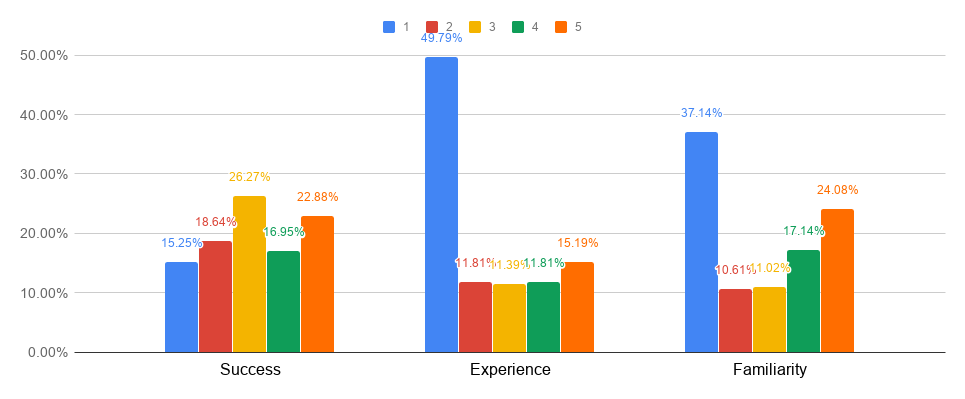

According to the data, 71% of participants answered they know this method well, and only (approximately) 12% didn’t know it. 59% had extensive experience with this method and only 23% answered that they didn’t have experience with it.

When we come to success levels we can see that 63% report they had success with this method.

Only (approximately) 13% answered that they didn’t have success working with a clear company strategy.

Using Periodic Work-Plans

A work-plan is a company's practical map – it determines what needs to be done in the following day, week, year (or whatever time period you determine). Organized and successful companies work with clear action plans which are determined by the company's vision and strategy on the one hand, and by actual performance and profits on the other.

The work-plan should include both the routine actions to be performed by employees, and the managerial steps which need to be taken by managers in all levels. Without a doubt, this is one of the most important management methods for every company, and every manager.

The data points to wide implementation of this method, and to considerable success with it.

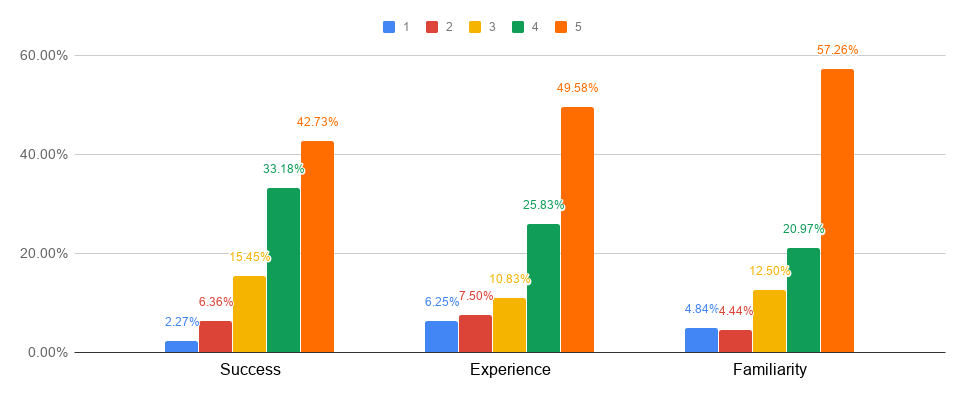

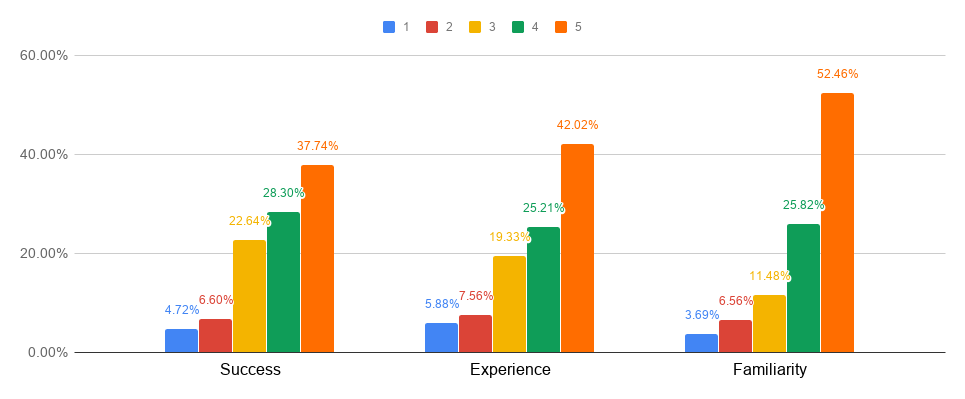

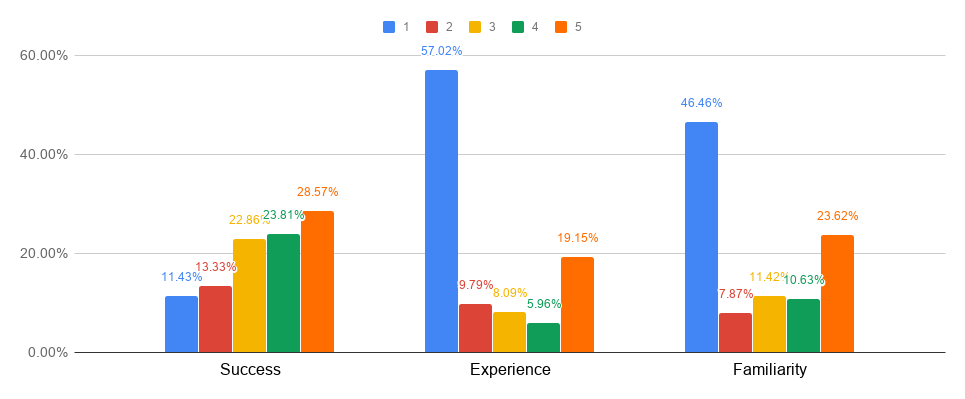

Over 78% of participants answered 4 or 5 in the familiarity question, while less than 10% answered that they aren’t familiar with it (1 or 2). Over 75% reported experience with the method, and only 14% reports no experience.

In the question on success, 73% of participants reported success working with the method – and less than 10% reported no success.

The survey shows that working with a periodic work-plan is one of the more successful methods, and companies who don't work with such plans should hurry and do so.

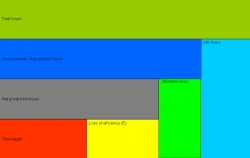

Using Key Performance Indicators (KPIs)

The KPI's a company uses periodically check the most important factors in its work: whether its percentage of depreciation, number of orders meeting deadlines, employee turnover rates, or any other KPI – a successful company can identify its important factors and measure them effectively – since without measuring KPIs it's almost impossible to achieve improvement.

In my experience, one of the leading causes for clear and fast improvement is the implementation of KPIs in companies that don’t work with them.

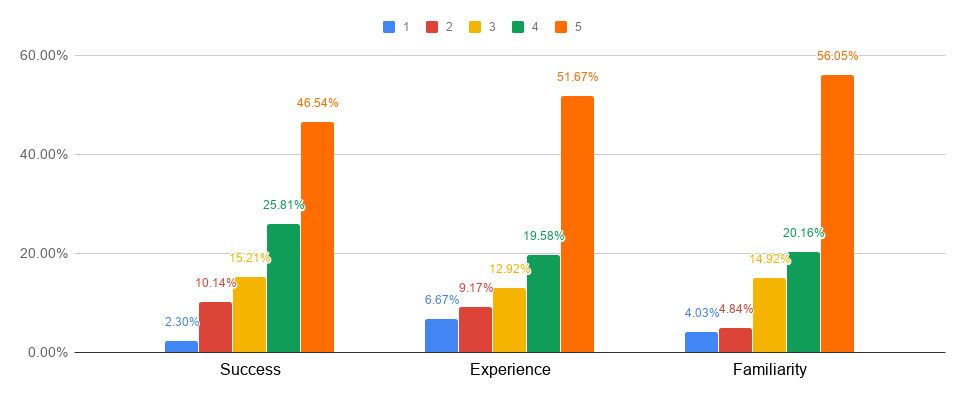

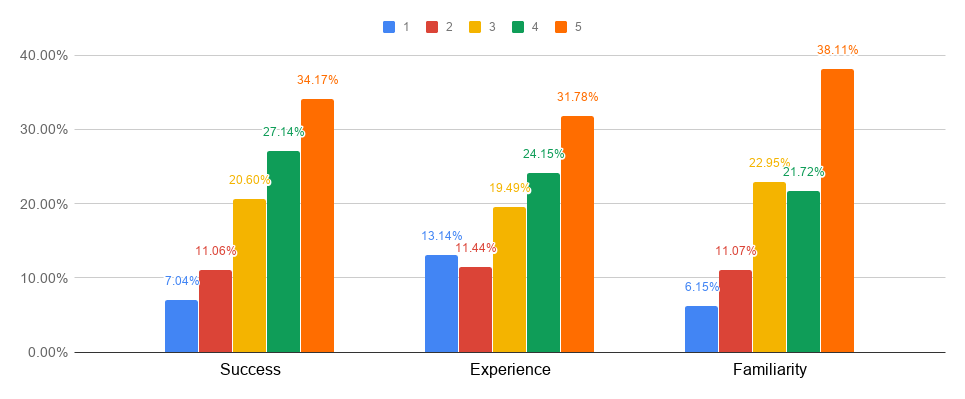

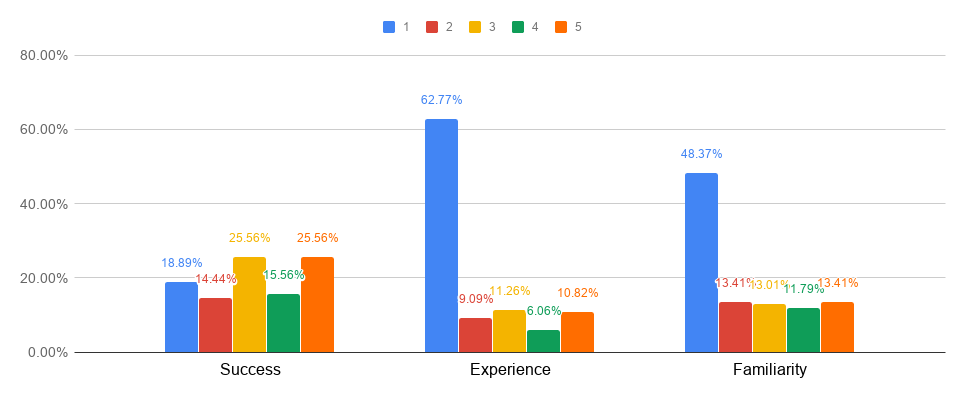

It seems this method is widely known: over 70% answered 4 or 5 in the familiarity question (meaning they know it well or very well), and only a little over 8% answered 1 or 2 ("barely know it" or "not at all').

Over 70% have also answered that they had experience working with the method, while close to 16% didn’t.

On success, over 72% (of participants who had experience with the method) reported success working with KPIs. Only 2.3% answered that they had no success working with them.

The data shows the importance and effectiveness of working with clear, accurate and measurable KPIs.

Setting Quantitative Goals

Setting quantitative goals goes hand in hand with setting accurate KPIs. The goals we set supply the required result for the KPIs – and they show us if we're succeeding in our work, and where we need to improve.

Goals are derived from the company's more general business goals, and tracking their progress will be done through monitoring of the KPIs set for various departments.

According to the data we can see that 81% of participants are very familiar with the method, and only (approximately) 9% aren’t familiar at all. Further, 76% of participants had experience working with quantitative goals, compared to 14% who had no experience.

When we come to the results for the success question, we can see that over 77% reported having success – and a little over 10% reported no success.

Here too the data indicates the effectiveness of setting clear quantitative goals, and the importance of implementing the method in companies that don't work with it yet.

Improvement Teams

Improvement teams are one of the main methods, and in my experience one of the most effective, for identifying and solving problems – in all levels. I work with them often, almost at every company I consult, and they create considerable improvements in every field they're employed in.

Such teams will usually be made up of employees from all levels of the company, sometimes from different departments, and will use various other methods (among others, also methods examined in the survey, like "fishbone", "5 whys", "brainstorming", and others) in order to analyze and solve the problems under their purview.

I highly recommend using improvement teams.

We are now coming to the less familiar methods, and we can see a decline in the percentage of participants who reported familiarity.

Of the participants, 59% answered that they're familiar (or very familiar) with the improvement teams method – and over 18% answered they aren’t familiar with it.

On experience, 49% answered 4 or 5, and over 33% reported having no experience with it. A considerable gap indicating the reality in Israeli industry, sadly familiar to me, where improvement teams aren’t valued enough and aren’t used in many companies.

55% of participants reported having had success or great success working with the method. Close to 27% answered 3' meaning they had moderate success, and over 18% of participants who had experience with the method reported no success.

If there are those among you who've worked with improvement teams and had no success – I suggest you examine the way you've employed the method and try and improve it – I emphasize again that improvement teams are one of the strongest and most successful management method I know.

Brainstorming

Brainstorming is a basic tool for analyzing and solving problems and faults in a company's production chain - and can be used in many cases – from management meetings, to improvement teams, and various discussion in all levels, circumstances, and topics.

An organized and professional brainstorming session can enrich management's knowledge base and bring to attention excellent ideas which often go unsaid.

78% of participants reported being very familiar or familiar with the method. Less than 10% reported little or no familiarity (1 or 2). 67% answered that they had experience with it and only 13% that they had none – and 66% of participants who had experience with it reported high levels of success, certainly a high number.

Only (approximately) 11% reported no success with brainstorming.

Sorting and Prioritizing Ideas

As managers we come across a wide variety of ideas and possibilities and must choose the ones correct for our company – many times without a real ability to predict the influence they'll have on the company's success.

For this reason, knowing how to prioritize different ideas and how to choose those most suitable is critical to the success of the company and us as managers.

60% of participants reported good or very good familiarity with the method. However, a relatively high number – 17% - reported no familiarity. 56% had experience working with it, while 24% had none.

61% of those who had experience working with this method reported having success with it.

Flowcharts

The flowchart method is a quality method used to identifying problems, bottlenecks, or faulty work procedures.

Working with a flowchart enables us to draw a simple and clear graphic representation of procedures, even complex ones or ones that take a lot of time – and thus identify critical points where both problems and opportunities are created.

65% reported familiarity with the method, and 16% reported having none.

Despite that, only 49% reported having experience with it, while 34% reported no experience.

52% had success working with a flowchart. A relatively large number answered 3 for this question – 29% of those who had experience with it. Close to 20% reported no success.

The Pareto Principle

According to the Pareto principle, also known as the 80-20 rule, defined by the Italian economist Vilfredo Pareto, 80% of activity or results is found in 20% of active factors.

It's a rule of thumb which enables us to focus on the important subjects – for example, focusing improvement actions and company resources only on the most profitable 20% of products – and thus create improvement in those places with the greatest potential to generate profit.

The data shows that 70% of participants are familiar with the Pareto principle, while 16% aren’t familiar with it at all.

Compared with the 70% who reported familiarity, only 45% reported experience working with the method, while 33% (a very high number) didn’t have experience with it.

As to success, 63.5% of participants who had experience with the method reported success – a very respectable number.

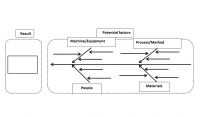

The Fishbone Method

The fishbone method is a great way to map the various reasons and procedures connected with a process, product or a certain point in the work – and thus gain a deeper understanding of what is happening in the company, and of opportunities for improvement or efficiency.

The goal of the method is to identify the reasons, causes or changes leading to an undesirable result. Its simple visual presentation aids the brainstorming process and makes it easier to see weak points that can lead to failure.

I use this method often when working with improvement teams or management teams, and warmly recommend its use in your company’s improvement processes.

The fishbone method is one of the least known in the survey, and the one who came last (!) in the success ranking. A fascinating result, since in my experience it's one of the better tools for finding and solving problems, both simple and complex.

Only 41% of participants answered they know the method, while 47% answered they do not. Over 37% chose 1 for this question - that is, no familiarity.

Further, only 27% of participants had experience with the fishbone method, compared to 61% (!) who had no experience.

In the success question 40% of participants who had experience with the method reported having had success with it, compared to close to 34% who reported no success.

The 5 Whys Method

The 5 whys method was developed by Toyota, as part of lean production. It's a simple and effective method used to identify the root causes for problems or other results in work procedures.

This method is usually used in conjunction with the fishbone method. After using the latter to brainstorm possible reasons for an undesirable phenomenon, and prioritizing them, we'll investigate the root causes of one or two of them. Once the root cause is found, corrective measures can be taken.

Such use will usually happen in improvement teams, in order to identify the root causes of a problem with a production process.

Only 34% of participants answered that they're familiar with the method, while over 54% answered that they aren’t.

An even lower number of participants answered that they have experience with the method – only 25% - compared to 66% who reported little to no experience – of them 57% reported no experience at all.

52% of participants who did have experience with the method reported success. Close to 25% reported no success.

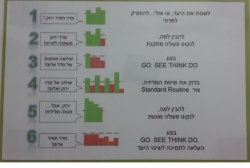

Go See Think Do Method

This is an excellent and orderly method for identifying root causes and starting corrective actions. Instead of hypothesizing about the root causes based on past experience, this method offers a different approach. First, it's employed by small teams of 3 or 4 people (a kind of small improvement team that meets once for a specific need), and second, the team uses some of the less familiar tools discussed above.

The first stage is "go and see": the team arrives at the location of the problem, asks questions, preppers a flowchart or another chart.

At the end of this stage the team narrows in on the problem.

The second stage is "think": using the fishbone and 5 whys methods the team identifies the root causes for the problem.

The last stage is "do": for every root cause discovered, corrective actions are taken and the plan's progress and success is monitored.

Only about 25% of participants were familiar with the method, while 61% didn’t know it. An even lower number had any experience with it – only 17% - and 71% had no experience. A very high number.

41% of those who had experience with the method reported success, while over 33% reported having no success with it.

Summary and Recommendations

In a previously published article on industry 4.0 I presented the necessity of competing both with the efficient and quality production from the West, and the cheap production from Southeast Asia.

In order to deal with this double threat companies need to implement the Industry 4.0 revolution. Many companies are hesitant, and thus put their future in danger. The government acknowledges the threat to the existence of local industry if it fails to successfully face this competition, and offers generous support for Industry 4.0 initiatives.

The required step-up isn’t centered only on computerization, robotics, and innovation, but also on ordered actions and using the methods reviewed in this article. The order should be:

- Creating a true vision (not one for the website) which is implemented in all levels of the company and all its actions.

- Creating a strategy based on the vision, meant to realize it.

- Setting goals towards acting on the strategy.

- Creating a work-plan based on the strategy and goals.

- A monitoring plan using KPIs to measure the work-plan's performance, over short timespans of a day, week or month (according to what's needed). If you want to achieve company goals – it'll be wrong to only monitor performance once a quarter, and often even monthly checks won't be enough.

- Remember that every company has more employees than managers. So in order to succeed it's important to get employees invested in company goals. The best way to do that is through improvement teams.

- Improving measured results by using brainstorming, the Pareto principle, and prioritizing. These methods can be used in every forum, and especially in improvement teams.

- Flowcharts, the fishbone method, and the 5 whys method are excellent and even necessary tools for improvement teams.

- Go See Think Do is a method which combines some of the above methods, and assists in solving problems.

All of the method surveyed in this article are excellent ones who had been developed over decades and have proven themselves in many companies.

If you're not familiar with them or failed to achieve success with them, I suggest you learn the best ways to use them.

If you are interested in my professional help, personally or for your company, the best way to contact me is to send a request through the Get in Touch form here.

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management