In the past, when I managed Osem-Nestle’s factory in Yokne’am, we often had improvement teams working with internal leaders.

For four years, we had a yearly workshop teaching employees how to lead improvements teams. The woman leading these workshops then led and managed the improvement teams, and coached the leaders. After four years, we transitioned to doing that internally as well.

Over time, I’ve learnt that many managers avoid leading improvement teams. They feel they are too busy and challenged in the normal course of their work, and don’t see any benefit to leading improvement teams.

Contrastingly, employees in non-management positions are often eager and excellent leaders. For them, leading a team is a great opportunity to do something meaningful and take centre stage.

Such employees would come to me asking to lead a team. Together we would find an issue that can improve profitability, and they’d start working.

About three or four years after starting, we had many teams working simultaneously, and out of around 370 employees, a 100 were taking part in improvement teams.

This activity got employees invested in company goals, and feeling meaningful and motivated, while also greatly increasing our profitability.

An Example of a Great Achievement by the Energy Efficiency Team

One day I was approached by Hikmat Halabi, one of our great improvement team leads, and an electrician in the maintenance department, who asked to lead a team focused on conserving and saving energy. It was a great idea. He gathered a team of six other employees, and they set out. At first their discussions were all over the place, but by the second or third meeting they decided to focus on the baking ovens, which had a high energy usage. They decided to focus on conserving energy used by these ovens. The solution they developed was amazing. It’s greatness lay in its simplicity and the money it saved. Exactly the kind of solution that can only come from people who work in the field. Managers and engineers, who come and go, will find it difficult to think of such solutions.

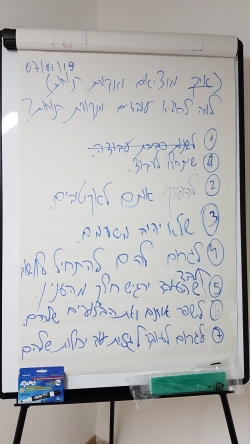

To summarize their solution: energy (gas and electricity) was being used even when the line was idling. They found that usage (when the line was working but not producing) cost 71,350 NIS a year for gas, and 57,895 for electricity (during 2003). The team suggested that when production was halted, the temperature in all warming units would be reduced to 100 degrees celsius. This would both enable a quick return to production, and create a significant reduction of energy consumption.

The above example is of an idea generated by a team lead, but there were of course cases where management initiated a discussion and appointed a team lead.

Kaizen was Born in the USA and Immigrated to Japan

In a previous article, I showed how the idea of small steps to improvement and employee participation was born in the USA during WWII, and was afterwards abandoned in the USA but adopted in Japan.

One of the main ideas in Toyota’s sixth principal is that employees are part of the problem, and so must be part of the solution. Another important idea is that employees should learn how to investigate faults in order to create improvements, and aren’t themselves subjects of investigations carried out by their managers.

A First Surprise: Working with Improvement Teams isn’t the Norm in Israel

We all want to feel meaningful, that we make a difference. That’s true for employees of all levels. Taking part in improvement teams and brainstorming sessions both creates this feeling of meaning, and adds interest in the work.

Additionally, working on problem solving exposes employees to company goals, and they can share their knowledge and experience. Often that’s information upper management doesn’t have. People who spend all their time in a certain place (a work-station, a warehouse, a customer service desk, or in the field with clients) can see things managers can’t see. Not because they’re smarter, but because they have a different perspective.

As mentioned above - employees who feel meaningful are more motivated. Working with improvement teams wasn’t our invention, but we saw the benefits - engaging employees with company goals and increased profits - and developed it. Success was amazing.

By the time I left Osem, I had become a great fan of improvement teams, and had a lot of experience working with them. I’d forgotten that outside of Osem, they were still a rare sight. Improvement teams as part of the operating culture were only used by a few specific companies. Usually international companies. Most companies in Israel weren’t even familiar with the idea.

That was, for me, the first surprise.

A Second Surprise: CEOs Resist Improvement Teams

About three years after leaving Osem, I started consulting, working with companies on improving profits. Usually, I tried introducing to the companies I worked with the method of improvement teams. Managers I met had one of three approaches to this:

- Some were initially resistant, but open to trying new things. They quickly discovered the benefits of working with improvement teams, and especially saw the new atmosphere this creates on the production floor. You can feel the increased motivation in the air. These managers stuck with the new way, and profited.

- Some were adamantly opposed to involving employees in brainstorming or sharing information. They looked down on their employees, and didn’t believe they could have anything to contribute, any information to share, or any solutions to suggest.

With such managers, there’s no possibility of involving employees. This path is closed. - Some managers were open to trying improvement teams, but only at the level of middle-management and above. These managers were unwilling to involve non-managers in decision making processes, or didn’t believe employees on the production floor have any understanding of the production process.

One manager at one of the large companies in Haifa Port explained to me that the production process was so complex, only engineers could understand it. This manager would periodically take part in improvement teams’ meetings, and was always surprised anew at the knowledge possessed by production floor employees. They weren’t engineers, but had spent years working on the production floor, and learned the chemical processes involved. Without this understanding they would have found it difficult to do their job.

This reality didn’t change the aforementioned manager’s opinion. Despite what he saw and heard, he remained insistent that only engineers could understand the chemical process.

An employee at that company shared once that, after working the production floor for over twenty years, it was enough for him to see the smoke rising from the factory's chimneys from his home overlooking the Haifa bay, to know what was happening in the factory.

Why?

Why were some managers unwilling to involve employees in tackling the company’s challenges?

I can only guess at the reasons based on what was said to me.

Confidentiality

This is mostly true in small companies. The assumption at the base of this reasoning is that the company will be hurt if competitors know information about it, and that any information shared with employees will be quickly shared with competitors.

Thus, the less employees know, the better.

Knowledge is Power

Some managers prefer to hoard knowledge, and so, in their mind, strength control over employees. This reasoning is expressed mainly by middle managers who rose from the ranks.

They don’t take into account or don’t value the information employees have, and that is lost due to the lack of open communication.

I Spent Years Studying, and They Hadn’t

Another reason that comes up often, explicitly or implicitly, is formal education: I, the manager, spent years studying at university, and so have thorough knowledge of what goes on in the field. Some production floor employees haven’t even finished highschool. What could they know that I don’t? This doesn’t take into account the fact that production floor employees spend many hours working the same area, or even the same workstation, and see things differently. They have information management doesn’t.

Whatever the reason, it’s very difficult to change the mind of managers who refuse to listen to employees.

How Do Resistant Managers React to New Information?

Reality isn’t black and white. It has a lot of grey. Even in companies where some managers resist involving employees in improvement processes, improvement teams can exist and succeed. Sometimes these will not include “field” employees, but only middle managers and above. Other times they will include “filed” employees despite some managers’ resistance.

Personally, I’m always willing to take on the challenge of working with improvement teams despite managerial resistance, because I believe success will be undeniable. I hope resisting managers who see the results of improvement teams and the important information coming from them, will change their minds and become cooperative.

In some cases this does happen. But in other cases, it doesn’t. Cases when, despite employees bringing incredibly important information to the table, such that can lead to a breakthrough or at the very least significant improvement - instead of appreciating the contributing employees - ego wins, and some managers will even confront employees about the information they shared in order to prove it isn’t valuable.

I often meet these confronted employees at the team’s next meeting, when they prefer to remain silent.

So What to Do?

Generally, I can say that when there is staunch resistance from managers, it will win. I write “managers” and not “management” on purpose, because this doesn’t only happen when all or most managers feel this way. It’s enough for some managers to be vocally against employee involvement in order to stop employees from taking part and contributing. In the absence of a determined CEO or another top executive who leads and promotes work with improvement teams, the culture of improvement teams won’t survive.

Summary and Recommendations

Working with improvement teams and involving employees in brainstorming sessions can bring a threefold benefit to every company:

- Provide new information unfamiliar to management. Not because employees are smarter than their managers, but because they see and are exposed to a different reality.

- Expose employees to company goals and get them invested in achieving those goals.

- Make employees feel meaningful, thus strengthening their motivation.

Seemingly this is an ideal culture that can benefit every company. But surprisingly, some managers strongly resist this way of work, sometimes irrationally. Such managers can thwart and even completely prevent employee participation, and the company’s attempts at getting employees invested in company goals.

Focused and Fast Coaching and Consulting Services for CEOs and Companies during the Coronavirus Crisis

The Business Excellence team can help you build, within 2-4 working days, a plan to survive this financial crisis, or to achieve your goals.

We can help you to do the following:

Build a plan to handle this crisis, and couch you through it.

Identify possible threats to your company and come up with a plan to approach them.

Implement and manage work-from-home practices.

Identify and maximize the opportunities (!) presented by the crisis.

Our experts have a wide and diverse experience of over 100 years combined managing companies and consulting to CEOs – so we will be able to identify the unique needs of each company, and find the safest and fastest way for you to approach the new challenges presented by the crisis, and to ensure your company’s resilience.

If you are interested in my professional help, personally or for your company, the best way to contact me is to send a request through the Get in Touch form here.

More Articles About Working with Improvement Teams:

- What Makes Improvement Teams Successful?

- How to Create and Measure Employee Motivation

- How Do We Build Employee Motivation?

- Excellence, Quality, and Increased Profits through Employees' Involvement and Responsibility

- How to Reward Employees for Proposing Improvement Measures?

- Old Kibbutz Values Have Been Revived in Leading Global Companies

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management