In some companies, working with improvement teams brings quick, clear, and considerable success. On the other hand, in others the work done by improvement teams is accompanied by frustration, and has no quick and clear results.

Why? What's the difference?

CEO Involvement

The most influential factor is the CEO's (or site manager's) involvement and investment in the process.

When the CEO is involved, checking up on progress and giving feedback (appreciation when progress happens, asking questions when the team is stuck), employees are energized and motivated, and the team has results.

When the CEO (or site manager) doesn’t care about the process, neither will the employees on the team.

When a CEO is the driving force behind beginning Lean Production (otherwise known as the Toyota Method), they should get the entire company onboard.

Employee involvement, especially improvement teams, is an important part of implementing Lean Production. As a result, employees feel they have a part in developing the company. Such a feeling is what gives each of us a sense of meaning and motivation.

It's important to note that a culture of working with improvement teams is common even without a wider Lean Production process.

When the CEO doesn’t believe employee involvement is important for improvement processes and for profit, the employees themselves will lose interest in improving the company.

Some CEOs don’t believe "simple employees" can or want to contribute to improvement processes.

In such cases improvement teams have a very low chance of succeeding.

How Can Improvement Teams Work Despite an Antagonistic CEO?

Sometimes CEOs compromise under pressure from their VPs. but in such cases, often, the CEO would want to "prove" that they were right all along, and show that despite cooperating with the VPs, the results support the CEO's initial resistance. You're probably familiar with such cases.

If a site manager was forced by the CEO to work with an improvement team, they'll "drag their feet" and "prove" there wasn’t any point in such work.

I was once invited by a COO who wanted to engage employees in reducing production waste. We met with the CEO, who said he would "allow" improvement teams as long as only team-managers and above take part. "Simple" employees have nothing to contribute.

I came across the opposite example at a company which had 24/7 production. The CEO arrived on Saturday afternoon when only a handful of employees worked the production floor, with no "supervision". The CEO was happy to see that the rules set by the improvement teams were implemented by the employees, and that they had a real interest in improvement.

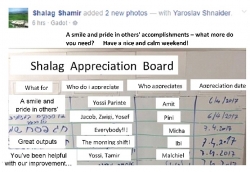

He wrote appreciative words on the appreciation board, and within minutes a photo of his words was sent amongst all employees in WhatsApp groups.

Other Necessary Factors for Success

Dealing with profit levers. Improvement teams need to, first and foremost, focus on the company’s most essential issues. Those whose improvement will lead to the most increase in profits. These are the company's profit levers.

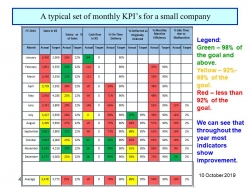

KPIs. Without monitoring and measuring KPIs we can't know if the team is progressing in the right direction, or at all. Employees and management will lose interest and improvements will stall.

Middle management. Middle managers, direct supervisors, can see themselves as improvement teams' main targets. Their direct reports are taking part in an activity they're not a part of, and they feel threatened. For this reason you should involve middle managers, in their own team which will discuss those issues raised in the improvement teams. Naturally, issues which concern them as managers will arise in the team, including their relationships with their reports.

Summary

The CEO is the most important factor influencing the success of improvement teams. When the CEO supports the process – it will succeed. A supportive CEO will give feedback and show appreciation, and will greatly benefit from the employees' resulting contribution and motivation.

The highest success rates can be seen in international companies where management makes a decision, which is then rooted downwards with the appropriate guidance, control, and progress monitoring.

On the other hand, when the CEO is against improvement teams, if those will even form, they'll die out.

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management