This article uses Jeffrey K. Liker’s book, The Toyota Way.

What are the first expenses you cut when sales are down? I don’t know about your specific company, but usually the first step is layoffs. Most often, labor costs aren’t the biggest expense, but it always seems simplest, fastest, and easiest to fire employees - and if and when sales are back up, recruit new ones. Furthermore, we know there is always latent redundancy, so we assume any reduction in the workforce will lead to greater efficiency.

Is It Really So Easy to Recruit New Employees?

Think back to the last time you recruited, was it really such an easy process? And when you recruit, how many of the new employees stay long term? Do you see, like many companies, employees come and go, as if you were a train station?

How much does it cost to recruit, interview, onboard and train new employees, and how many new employees leave even before training is completed? During the last round of layoffs, you let experienced employees go, maybe even licensed machine operators. How much will you pay, when the time comes, to recruit and train replacements?

Getting Employees Invested in Company Goals

The topic of getting employees invested in company goals is often discussed on this blog - we can see a significant difference in results between companies whose employees are invested, and those whose employees aren’t. But can you imagine employees becoming invested if they know that at the first hurdle, you’ll fire them?

Base Your Managerial Decisions on a Long-Term Philosophy

In his book The Toyota Way, Jeffery K. Liker presents Toyota’s 14 principles. The first is - base your decisions on a long-term philosophy, even at the expense of short-term financial goals.

Liker describes how, in the early 1980’s, Toyota and GM opened a new factory in the US. This was Toyota’s first overseas factory, and they didn’t want to manage it on their own. They had no problem teaching GM their manufacturing techniques (TPS). So the two companies jointly re-opened a factory closed by GM two years before. They re-hired employees who’d worked at the GM factory, including union leaders, since they felt they had leadership qualities. They then sent those union leaders to train at a factory in Japan for three weeks. The union leaders witnessed Toyota’s manufacturing system first-hand, and came back to the US “converted”. They believed in the company, and convinced more skeptical employees to get on board.

Building Trust

Dennis Cuneo, the then CEO of the factory, said that the key was building trust with employees. 1987 and 1988 saw a decline in sales, and manufacturing was reduced by 75%. But there were no layoffs. Instead employees were included in improvement teams, and given other useful tasks. According to Cuneo, the most important thing they did, though, was build mutual trust.

How Toyota Created Profit

According to Cuneo, Toyota didn’t measure success by quarterly reports, but by the continued respect felt by clients and employees. They believed that their skilled and committed employees will help increase efficiency and eliminate waste. In the long term, this is what they saw as the key to profit.

I see this as a key factor in Toyota’s success - skilled and committed employees help increase efficiency and eliminate waste. Instead of laying off employees, Toyota gets them invested in company goals.

Following a near bankruptcy after WWII, Toyota made a commitment to eliminating unnecessary costs, and has maintained a meticulous budget monitoring system overseeing expanses of all departments monthly, down to the smallest detail.

Hotbeds of Waste

In my article Hotbeds of Waste: Where We Lose Major Money Without Noticing, I highlighted Toyota’s method of identifying waste, according to which hotbeds of waste are:

Defective products,

Overproduction,

Transport,

Stand-bys,

Inventory,

Excess motion,

Processing.

Look at your own company, how many of these exist and are given little to no attention? These are hidden costs, mostly because they have no dedicated rubric in accounting. If you don’t add up the cost of overproduction, for example, how can you know how high it is?

Furthermore, overproduction is a common “efficiency” measure in many companies, as is defective products (do you sell second rate products? If you do, you legitimize the continued production of such stock, and the accompanied waste), excess inventory, etc.

Toyota sees employees as an essential partner to preventing wastes and increasing profits, and not as a cost that must itself be minimized whenever sales are down.

Toyota’s Vision in North America

It’s interesting to look at Toyota’s vision in North America, to better understand its method. It includes the following:

- As an American company, Toyota contributes to the economic growth in the US.

- As an independent company, it contributes to the stability and welfare of its employees.

- As a member of the Toyota Group, it contributes to the group’s overall growth.

Note that this vision doesn’t include goals like “provide dividends to shareholders”, despite Toyota being a publicly traded company. Shareholders profit because the company puts its employees and clients first.

Summary and Recommendation

I presented Toyota’s first principle, as it appears in Liker’s book The Toyota Way: base your decisions on a long-term philosophy, even at the expense of short-term financial goals.

Don’t see labor as a “variable cost”, that should be minimized whenever sales are down. Toyota sees its employees as partners in efficiency processes, in producing quality products, and in eliminating waste. They adhere to the principle of not letting business considerations undermine mutual trust and respect.

Can you look at your company similarly?

Do you see your employees as true partners in success?

How much are mutual trust and respect principles of your company?

Focused and Fast Coaching and Consulting Services for CEOs and Companies during the Coronavirus Crisis

The Business Excellence team can help you build, within 2-4 working days, a plan to survive this financial crisis, or to achieve your goals.

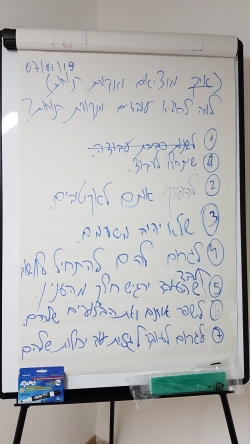

We can help you to do the following:

Build a plan to handle this crisis, and couch you through it.

Identify possible threats to your company and come up with a plan to approach them.

Implement and manage work-from-home practices.

Identify and maximize the opportunities (!) presented by the crisis.

Our experts have a wide and diverse experience of over 100 years combined managing companies and consulting to CEOs – so we will be able to identify the unique needs of each company, and find the safest and fastest way for you to approach the new challenges presented by the crisis, and to ensure your company’s resilience.

If you are interested in my professional help, personally or for your company, the best way to contact me is to send a request through the Get in Touch form here.

My First Book: Manage! Best Value Practices for Effective Management

My First Book: Manage! Best Value Practices for Effective Management